Headbox for Paper Machines

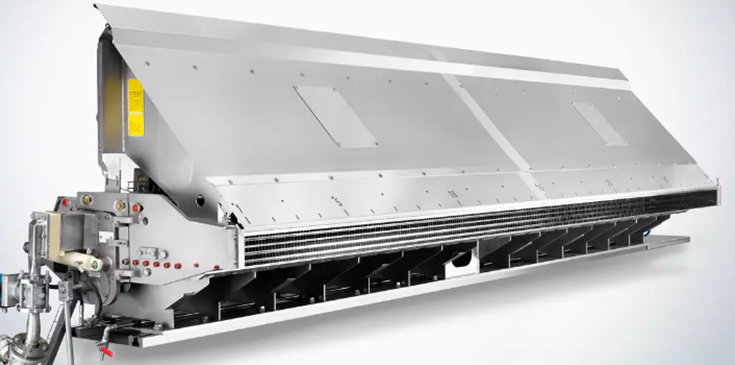

a) Pressurized Headbox

The pressurized headbox is operated by the pressure of the air. The pond level is maintained at a certain point. Above that level, it contains pressurized air. The head determines the slice jet speed that contains two to three rectifier rolls.Applications & Salient Features

- Shape difference across the deckle in max ±2 GSM

- Manifold is offered as per the quality and production capability

- Speed up to 250 m/min to 500 m/min respectively

- Slice width up to 8000 mm

Advantages

- Gives excellent results with all types of papers

- Sturdy and durability provides long-life

- Reliable performance

- Low maintenance

- Power saving

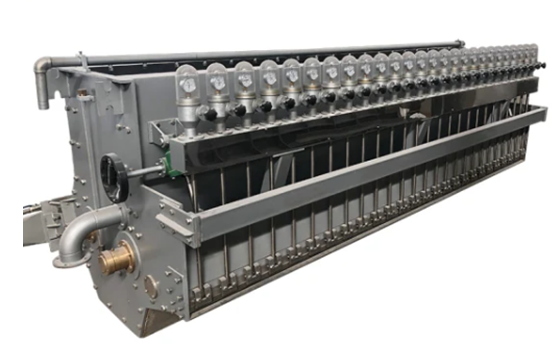

b) Hydrolic Headbox

Hydraulic headboxes are designed for twin-wire forming.

These types of headboxes are available with or without a stabilization chamber. The stabilization chamber is a tube bank(turbulence generator) that is present between the chamber and the slice. Improving the velocity profile of the cross-section is the main function of the tube bank.

Applications & Salient Features

- Manufactured with high-quality material & modern techniques

- Used for high-speed machine operations

- Can produce higher grade writing/printing papers, coated/uncoated duplex board, tissue papers, etc.

- Speed up to 500 m/min & 1500 m/min respectively

- Slice width up to 8000 mm

Advantages

- Compact size, therefore, requires less floor space

- Higher safety and reliability of operations

- User friendly

- Low maintenance

- Power saving